Glass Defects And Guidelines

The Complete Guide

WHAT’S THE STANDARD FOR GLASS QUALITY? WHERE CAN I FIND OUT INFORMATION ABOUT STANDARDS?

What is the Glass and Glazing federation (GGF)?

GLASS TYPES – WHAT’S THE DIFFERENCE?

Glass used in buildings is mostly made from ‘float’ glass. Sometimes, extra processing is done to make it safer, more secure, and energy efficient. The two main types of strengthened glass are ‘toughened’ glass (heat treated) and ‘laminated’ glass.

Glass can be coated to control the amount of solar heat or thermal energy that passes through it. It can also be screen printed, coated with ceramic frit (which fuses ceramic enamel to the glass), or have its surface altered to provide decoration or privacy. These options are discussed in more detail below.

Our windows come in double or triple glazed models. Each pane of glass can be one of three types, with additional coatings or visual characteristics.

Additional Glass Options

DOES THE TYPE OF GLASS I HAVE AFFECT ITS OPTICAL QUALITY?

WHAT’S NORMAL?

HOW SHOULD YOU INSPECT YOUR GLASS?

- Insulated Glass Units (IGUs; the glass in your windows) should always be viewed from the inside at or near right angles to the glass. Inspecting windows from an oblique angle is inherently more likely to display ‘normal’ characteristics of the glass, such as haze, and confuse the observation.

- Inspect from at least 3 metres away – imperfections must be visible from this distance.

- View the glass in natural daylight and not direct sunlight

- There should be no visible moisture on either the inner or outer glass panes

- Strong lamps and / or magnifying glasses should not be used

- A time limit of 1 minute per m² is allocated for viewing

- Focus on the central 80% of the glass (Zone M as discussed below).

WHAT IS AN ACCEPTABLE DEFECT? WHAT’S NOT ACCEPTED?

Standards for faults in Float glass

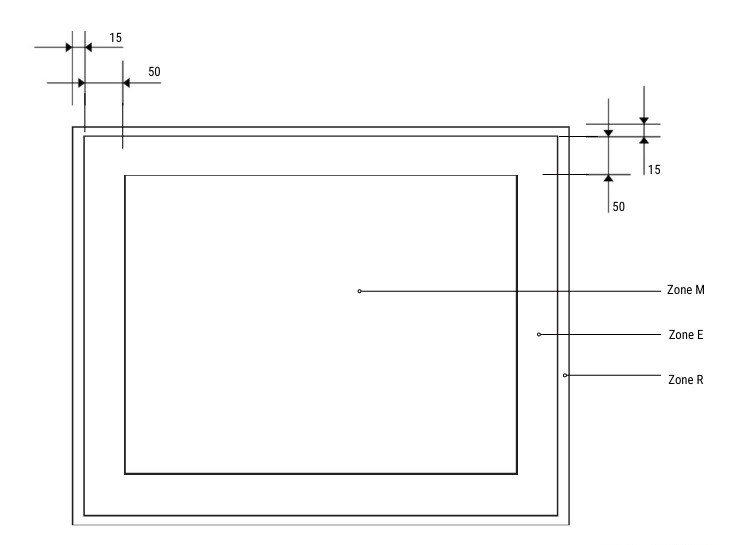

- Imperfections within 15mm of the edge – ‘Zone R’ according to the GGF, and an area usually covered by the frame or edge seal – are all acceptable regardless of size or frequency.

- Imperfections within 50mm of Zone R – that is, within 65mm of the edge; ‘Zone E’ – are accepted or rejected based on the size of the fault, the size of the glass, and the frequency in which such faults occur.

- Imperfections in the remaining centre of the glass – ‘Zone M’ – are accepted or rejected based on the size of the fault, the size of the glass, and the frequency in which such faults occur.

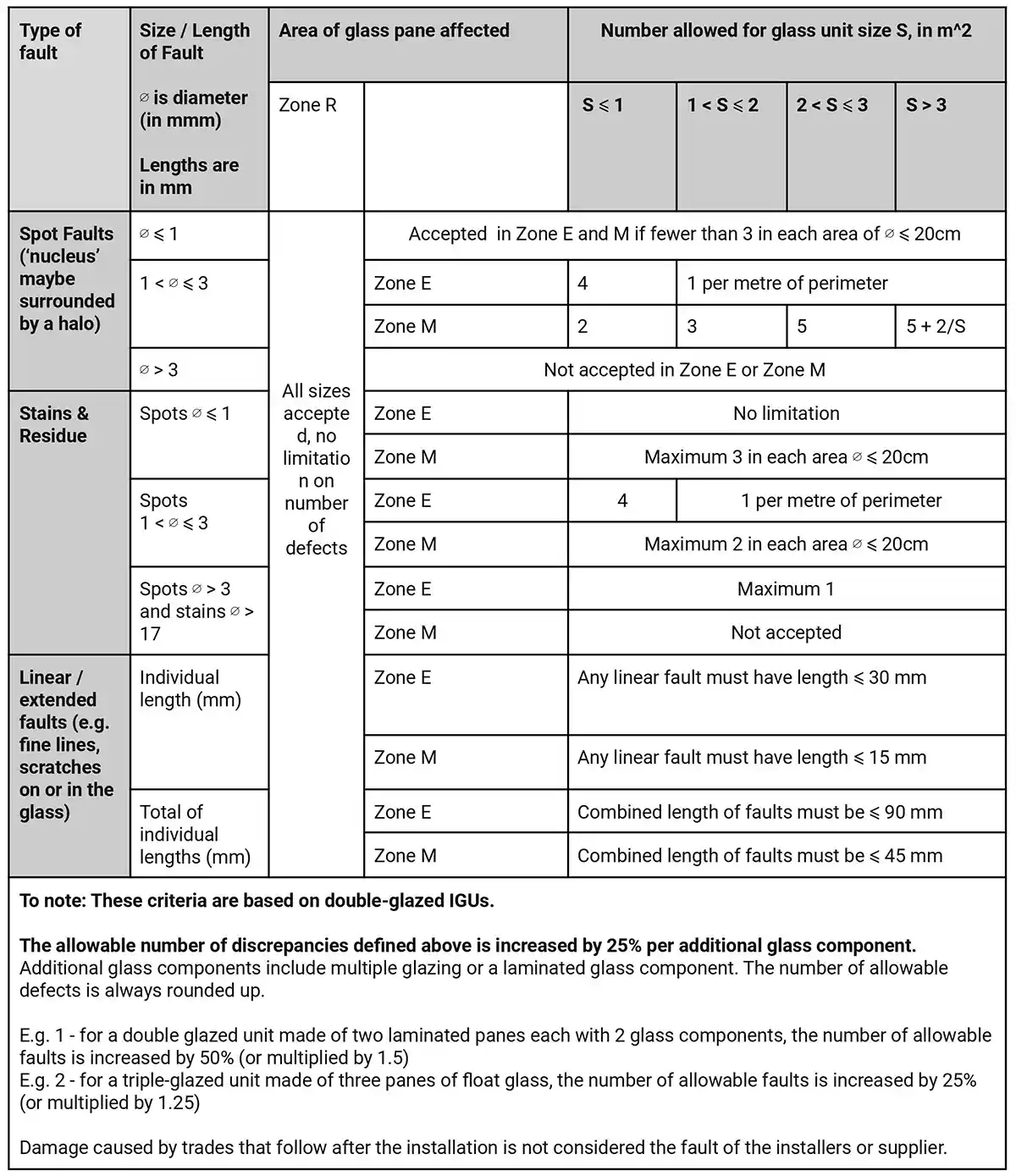

Imperfections in float glass are divided into categories and evaluated as follows:

At first glance, this looks like an intimidating amount of information. What is it actually telling us?

- Glass quality is judged by looking through the glass, not at it. This is why the obtrusiveness of faults are judged by how frequently they appear in a given area, and how close they are to the middle of the IGU.

- The closer to the central area of the glass, the fewer faults are accepted. All imperfections within 15mm of the edge are considered acceptable, but the central Zone M is subject to much more stringent requirements for visual quality.

- Determine which area of the glass the fault is in first, then attempt to categorise the type of fault – this may need assistance from our aftercare team, as it will not always be obvious.

- Use the table to evaluate the fault.

- An extra allowance is made in the allowable number of discrepancies for triple-glazed IGUs and / or those containing laminated glass. Pay careful attention to this extra permission when counting any imperfections in these units.

- Follow the guidance at the bottom of this article if you believe the fault falls in a rejection category.

WHAT ABOUT MARKS INSIDE THE GLASS?

STANDARDS FOR FAULTS IN TOUGHENED GLASS

STANDARDS FOR FAULTS IN LAMINATED GLASS

SO WHAT SHOULD YOU DO IF YOU SPOT AN IMPERFECTION?

- Check the glass type from your window schedule.

- Review the guidelines for assessing glass.

- Inspect the glass, noting the size, frequency and type of each imperfection visible from the given distance. Take images if necessary.

- Compare your findings with the GGF table of critical measures for faults, taking into account any tolerance accorded your IGU type.

- If you believe the fault is not acceptable, get in touch with us on 01554 750031 or email sales@atcostwindows.co.uk to discuss the query and your options.